Production and technology

Our responsibility

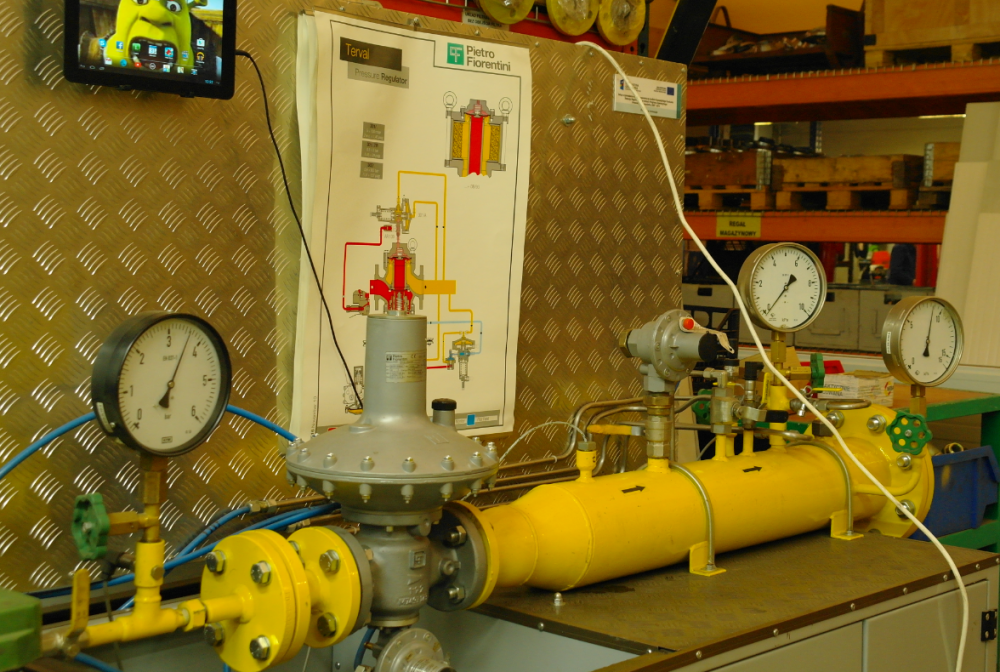

It is hard to imagine a responsible manufacturer of gas fittings and a leader in innovations in gas industry in this part of Europe to not have a perfectly operating in-house lab.

Our production quality monitoring laboratory operates according to the implemented Quality Management System EN ISO 9001:2009 and other internal procedures for specific products, but also pursuant to individual requirements of our Polish and foreign clients.

We are probably the most technologically advanced company operating in the gas sector in Europe, and most definitely in Poland.

The purpose of the existing manufacturing procedures is to ensure repeatable production by close supervision of the process of manufacturing gas fittings, from the moment of acceptance of raw materials and their storage, through the actual production, marking and packing, to warehousing and distributing the products.

Technology and automation

We have the newest equipment, machinery and devices and the latest test beds available in the gas sector. We have extensive technological facilities and capabilities that allow us to offer top quality products. Thanks to our spacious warehouses, clients have constant access to the needed goods.

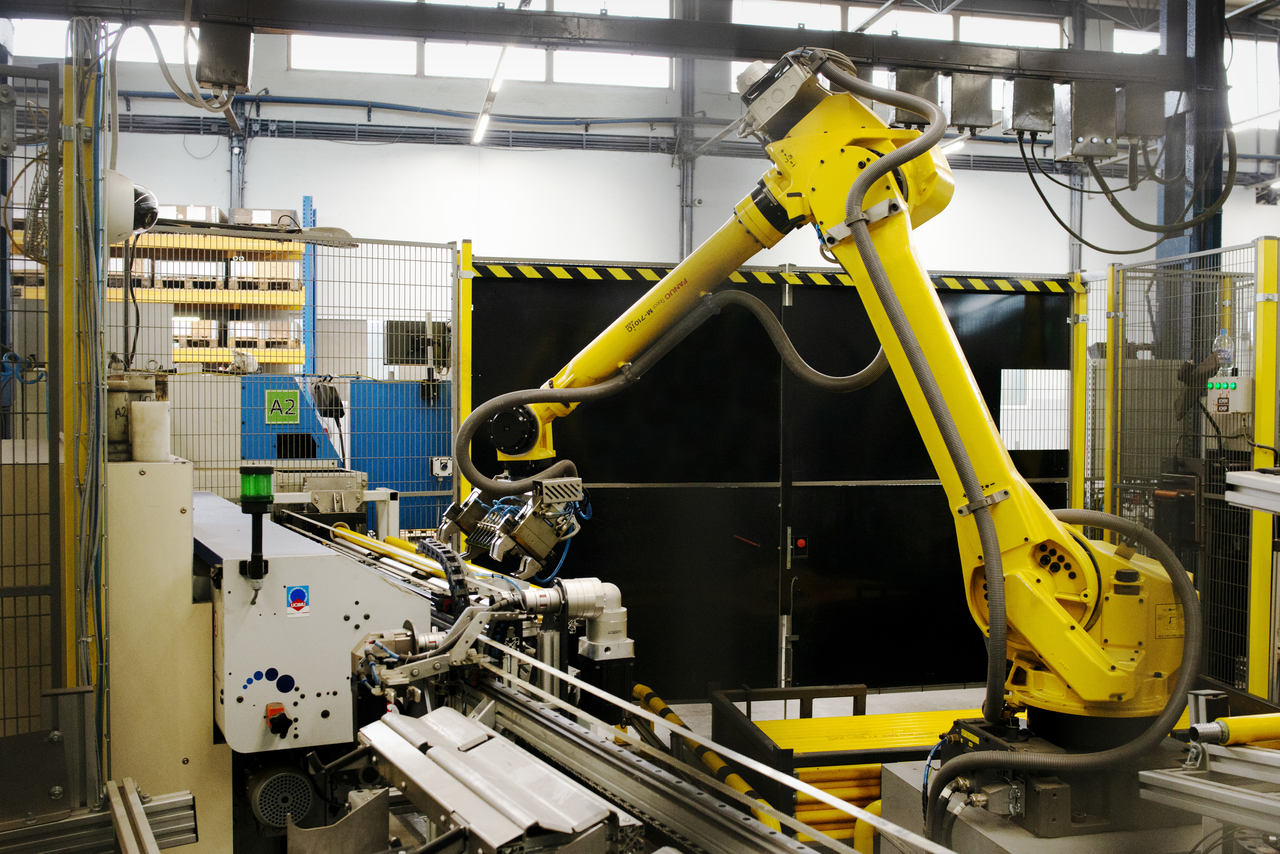

The automation used across numerous production areas ensures:

- Production capacity to satisfy 100% of the market’s needs.

- Top quality that is repeatable for every single item.

Technology and quality

Machine park

We never stop investing in acquiring modern technologies. We adapt such tech to our needs and expand our equipment with new, innovative production devices. Thanks to the latest technological developments we can offer gas products that are safe and of the highest quality.

CNC processing

Line for manufacturing metal cabinets

Line for manufacturing metal cabinets

Welding robot

CNC processing with a robotised feeding system

Automated production line

Sand blasting machine

Lathe

Manual welding

Powder coating